Enhance Building And Construction Performance With Professional Steel Fixing

In the world of building, the duty of expert steel taking care of can not be overemphasized, as it directly affects both the architectural integrity and performance of jobs. Experienced steel fixers use their experience to guarantee specific placement and safe connecting of reinforcements, which is essential in reducing expensive errors and maximizing product usage.

Significance of Steel Repairing

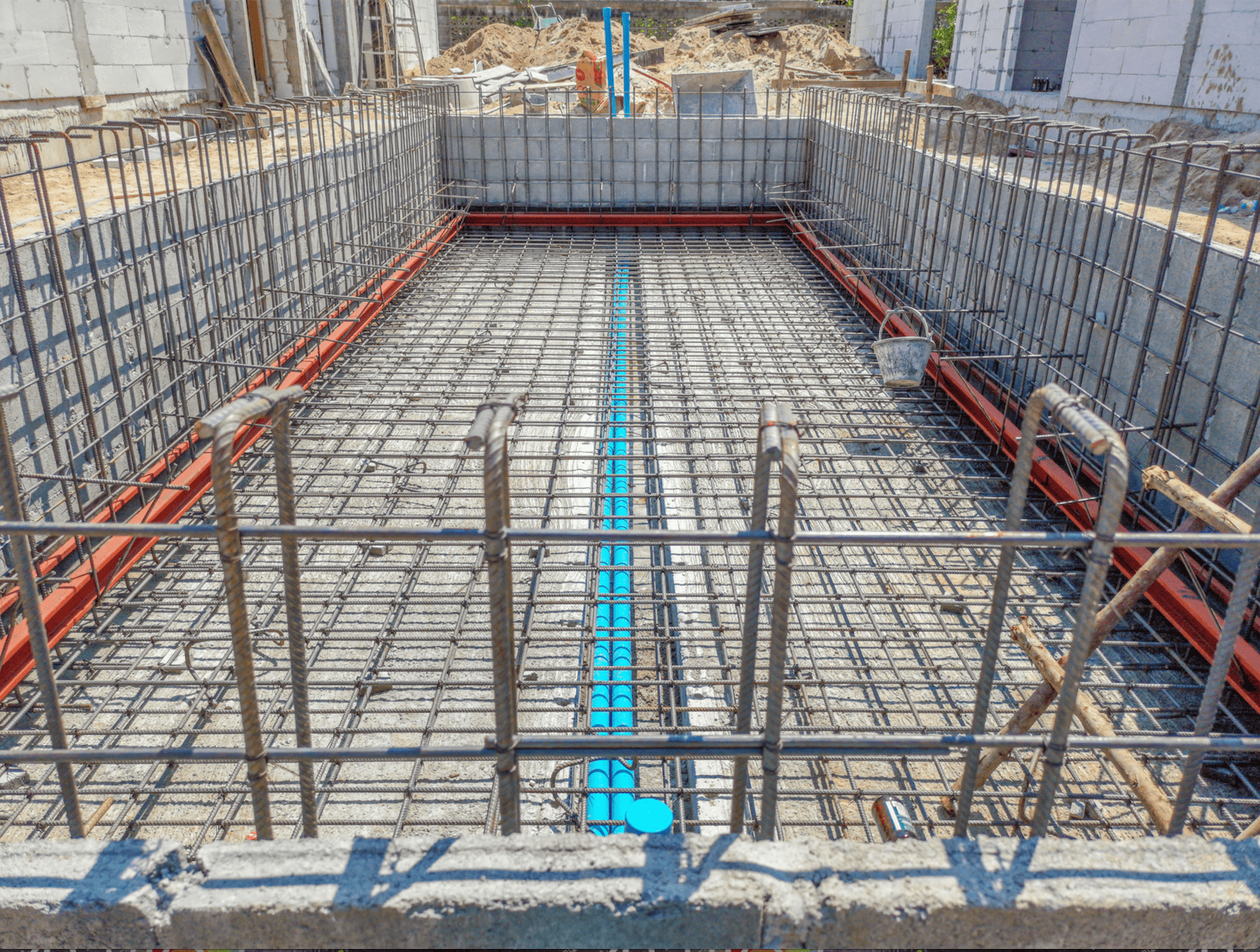

Why is steel fixing a vital component in construction? Steel repairing includes the positioning and safeguarding of steel reinforcement bars (rebars) within concrete structures, making sure structural integrity and durability.

Furthermore, the precision entailed in steel taking care of straight impacts the general high quality of construction. Precise placement of rebars makes sure that layouts are complied with, reducing the risk of structural weaknesses. Additionally, steel repairing adds to the efficient transfer of lots within a structure, permitting for the building of safer and much more resilient buildings.

In addition to improving architectural performance, steel repairing additionally plays a role in enhancing building timelines. Hence, comprehending the importance of steel taking care of is basic for professionals in the building and construction industry, as it creates the foundation of secure and lasting frameworks.

Benefits of Expert Competence

Additionally, seasoned steel fixers are experienced at analyzing building and engineering strategies. Skilled steel fixers are trained in industry requirements and ideal methods, which aid to alleviate threats connected with steel work.

Additionally, utilizing specialist services can lead to a lot more reliable use products. Experts can enhance the amount of steel needed, hence reducing material expenses and decreasing waste. This performance not just benefits the spending plan yet additionally straightens with lasting construction practices.

Finally, relying upon expert competence promotes a collaborative setting among engineers, engineers, and service providers, advertising seamless communication and job execution. Overall, the benefits of professional proficiency in steel dealing with are invaluable, significantly influencing the success and top quality of building projects.

Methods for Effective Steel Correcting

Reliable steel dealing with techniques are important for ensuring timely task completion and optimal architectural efficiency. One of the primary strategies entails specific preparation and format of rebar positionings based upon structural illustrations. Using innovative software program for 3D modeling can assist in much better visualization and coordination among the job team, lessening mistakes during setup.

Additionally, employing proper securing techniques, such as cord connecting or mechanical couplers, can boost joint stability and decrease labor time. Training employees in best practices for safety and efficiency is likewise essential, as proficient employees can perform jobs a lot more rapidly and properly.

Last but not least, regular evaluations throughout the setup process can aid identify and fix potential concerns early, preventing expensive hold-ups. By incorporating these methods, building and construction jobs can attain improved efficiency and enhanced structural high quality, eventually delivering much better results for customers and stakeholders.

Typical Obstacles and Solutions

While carrying out reliable techniques can dramatically boost steel dealing with procedures, numerous obstacles frequently arise that can impede progress. One usual challenge is the miscommunication between groups, bring about mistakes in steel placement and raised rework. To resolve this, establishing clear communication methods and using innovative software program for control can boost accuracy and synergy.

An additional considerable issue is the irregularity in site conditions. Unforeseen variables such as climate adjustments or ground instability can disrupt steel repairing procedures. A proactive option includes conducting thorough site analyses get more and having backup strategies in position to mitigate possible hold-ups.

Additionally, labor shortages can impede the timely completion of steel dealing with jobs. Buying training programs and cultivating a culture of ability advancement amongst workers can assist bridge this gap.

Finally, inadequate safety measures can posture risks to both employees and the job timeline. Applying rigid security protocols and normal training sessions can improve employee safety and minimize accident-related interruptions. By recognizing these challenges and implementing efficient solutions, building and construction specialists can ensure an extra trustworthy and efficient steel dealing with procedure, ultimately causing effective project outcomes.

Effect On Task Timelines

The effect of steel repairing on job timelines is a vital consideration for construction specialists. Reliable steel repairing straight affects the total timetable, as delays in this phase can result in substantial problems in subsequent building activities. Appropriately carried out steel repairing ensures that the architectural honesty of the task is attained in a timely fashion, helping with a smooth shift to the next phases of building.

When steel repairing is performed by skilled specialists, the risk of errors and revamp is reduced, promoting adherence to the intended timeline. Conversely, poor steel fixing can result in pricey delays, calling for added time for adjustments and evaluations. The integration of advanced strategies and see it here modern technologies in steel fixing, such as 3D modeling and prefabrication, can better boost effectiveness, enabling quicker installment and lowered labor expenses.

In addition, prompt conclusion of steel fixing effects the organizing of other trades, such as concrete finishing and pouring job. steel fixing. By focusing on professional steel dealing with, building teams can successfully manage their timelines, making certain projects are provided on time and within budget plan. Eventually, investing in top quality steel dealing with solutions is important for preserving job momentum and achieving effective outcomes

Verdict

In conclusion, expert steel fixing plays an essential function in improving construction efficiency by making certain the exact positioning and safe and secure connecting of steel reinforcements. Prioritizing specialist knowledge in steel dealing with is important for the success of building projects.

Steel taking care of includes the positioning and securing of steel reinforcement bars (rebars) within concrete frameworks, ensuring architectural integrity and resilience. Knowledgeable steel fixers are trained in industry requirements and best techniques, which aid to reduce dangers associated with steel work.

By acknowledging these difficulties and implementing effective options, building and construction experts can make sure an extra trusted and reliable steel fixing process, inevitably leading to successful project outcomes. (steel fixing)

By prioritizing expert steel fixing, building and construction groups can successfully manage their timelines, making sure jobs are supplied on timetable and within budget plan.In conclusion, specialist steel repairing plays a vital function in enhancing construction performance by ensuring the exact placement and protected tying of click for source steel reinforcements.